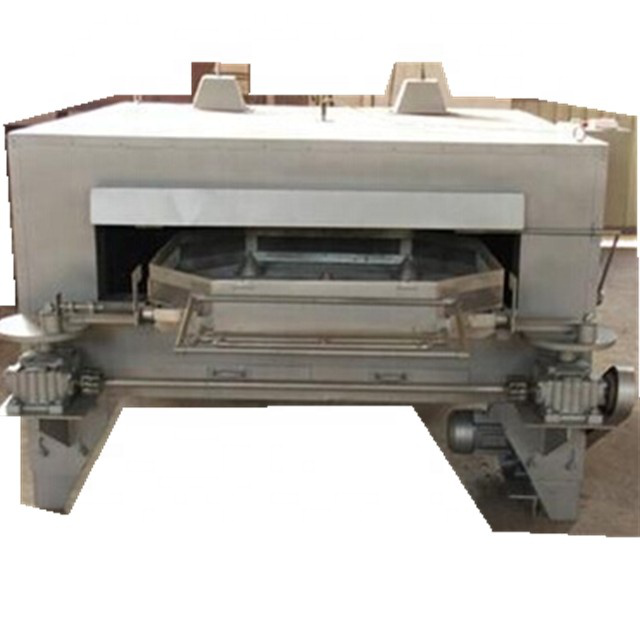

Peanut Bakery Equipment

Features of Peanut bakery equipment: 1.Gas roaster is made of metal and it is a single-body roaster. It has a simple structure and it is very easy to operate. This machine uses the cycloidal reducer as power, and the chains drive the turning cage to roast the materials. Peanut brittle bar making machine Adopt the way of infrared heating to roast the materials by heat radiation from the pipe heaters. The working temperature can be well controlled because this machine has a automatic temperature cont...

Description

Features of Peanut bakery equipment:

1.Gas roaster is made of metal and it is a single-body roaster. It has a simple structure and it is very easy to operate. This machine uses the cycloidal reducer as power, and the chains drive the turning cage to roast the materials.

Peanut brittle bar making machine

- Adopt the way of infrared heating to roast the materials by heat radiation from the pipe heaters.

- The working temperature can be well controlled because this machine has a automatic temperature controller.

- You can choose machine which all made of 304 stainless steel or the machine whose outer is made of carbon steel and whose inner turning cage is made of 304 stainless steel.

Peanut bakery equipment

Product description of the peanut roasting machine:

- This machine is made of metal and it is a single-body roaster. This machine uses the cyclical reducer as power, and the chains drive the turning mesh cage to roast the nuts. So, the nuts could be roasted evenly. No burning situation happened.

- The roaster adopts the way of infrared heating to roast the nuts by heat radiation from the pipe heaters. After then the infrared heating cooks the nuts inside the mesh turning cage. Delicious and healthy.

- The difference between gas-fired and electric-fired cashew nut roasting machine as follows:for gas-fired roaster, it adds burner, the power is comes from the gas burring, when comes to electric-fired roaster, there are heat pipes on the bottom of the roaster, the heat piper will release power directly after get through electric. The rest feature about electric roaster just same to gas one.

- This equipment is equipped with automatic temperature controller and time controller. Operator could adjust the roasting temperature and roasting time for every batch according to the different nuts.

- This machine could be used for roasting peanut, chickpea, walnut, cashew nut and hazelnuts etc.

Technical parameters

| Power supply | 380V±10% 50HZ±1% three-phase five-wire |

| Microwave Output Frequency | 2450±50MHz |

| Microwave input apparent power | ≤21KVA |

| Microwave output power | ≥15KW |

| Microwave power adjustment range | 0-15KW(adjustable) |

| Ambient temperature | -5-40°C |

| Relative humidity | ≤80%, Surrounding environment:no corrosive gas, conductive dust and explosive gas |

| Overall dimension(L*W*H) | about8420*840*1750 mm |

| Transmission speed | 0-10m/min(adjustable) |

| Height of the inlet and outlet | 60 mm |

| Microwave leak | accord with a country GB10436-89 standards(<5 mw/cm^2) |

| Equipment safety | accord with GB-5226Electrical safety standard accord with a country GB16798-1997 Food machinery |

Peanut bakery equipment

Working principle

Using the flame of solid fuel(coal,charred or firewood both are adoptable)directly heating the machine, so it can transfer the heat energy to peanut. The peanut go round and round in the machine; it will increase its temperature and plasticity, evaporation of water, decrease in viscosity and discover, it is better for baking.

- This peanut roaster machine is used to roast the peanut before peeling the red skin. After roasting the peeling rate is high, the broken rate is under 5%.

2. This peanut roaster machine uses gas or electricity as fuel, uses the new type heat pipe as heat-conducting medium.

Taking advantage of the cycling of hot air in the pipe, the roster cans exposure the heat energy to the baked object.

- 3. Peanut roaster machine is made of metal and it is a single-body roaster. It has a simple structure and it is very easy to operate. This machine uses the cycloidal reducer as power, and the chains drive the turning cage to roast the materials.

After years of effort and innovation, with professional production and processing factories,complete and scientific quality management system. Advanced production technology, to provide our clients with quality and cheap products but good services.

The company exports a wide range of products:Asia: Russia, Uzbekistan, Korea. Japan. etc.

Southeast Asia,Thailand, Vietnam, the Philippines, Singapore and SO on;South Asia: India, Pakistan;

Africa: Kenya, Ghana, Tanzania. Nigeria, Ethiopia, South Africa, Burundi, Djibouti, Cameroon,Congo and so on,Middle East! Saudi Arabia, Lebanon, Israel, Oman, Turkey, Iran and so on;Europe: Germany, Switzerland, UK, Hungary, Spain, Cyprus

America: the United States, Mexico, Brazil, Chile, Argentina and so on,Oceania Australia, New Zealand.